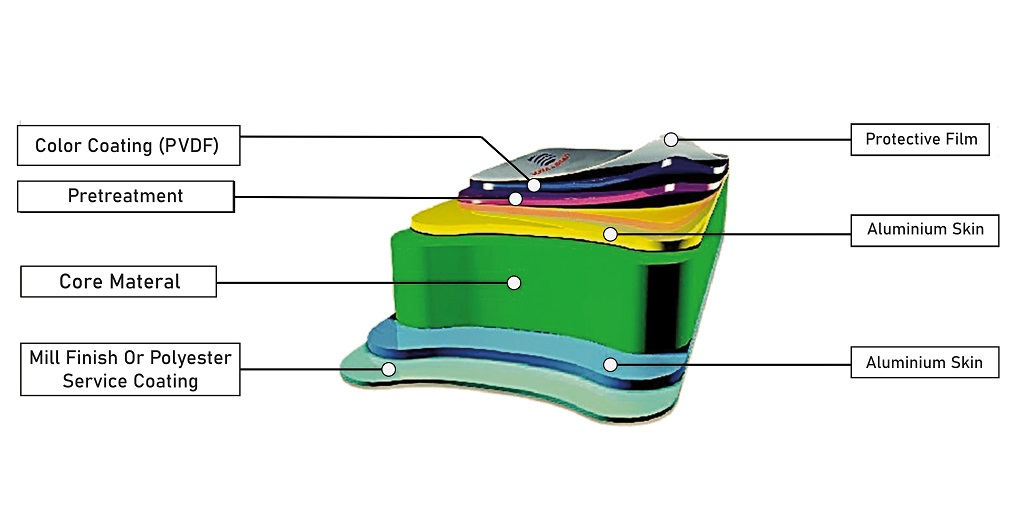

WELLBOND ACP is basically composed of the following materials:

| STANDARD | According to the ASTM and international standard ESO 2013/7630, SASO 2008/2752 |

| SPECIFICATION | WELLBOND Aluminum Composite Panel is a high-Performance Product Consisting of two Sheets of 0.5 mm Aluminum permanently bounded to each side of an extruded thermoplastic compound core material |

| WIDTH | 1240 mm, 1570 (Maximum) |

| LENGTH | 2440 mm, Upon customers request |

| STANDARD SIZE | 1240 (width) x 3200 mm (length) x 3 mm (thickness) 1240 (width) x 5600 mm (length) x 4 mm (thickness) |

| NORMAL COLOR | 40 kinds of Aluminum Composite Panel 7 kinds for Granite grain Panel Note: Special colors are available according to customer’s request |

| APPLICATION | 1. Building exterior curtain walls 2. Decoration for renovation of an old building 3. Decoration of interior wall, ceilings and kitchen 4. Shop’s door decorations 5. for Advertisement, display platforms and signboards 6. Wallboard and ceilings for tunnels 7. Industrial materials, Vehicle and materials |

A high non-reactive and pure fluoropotymer

coating used in applications requiring the highest purity, strength, resistance to solvents, acids, bases and heat, and low smoke generation during a fire event. PVDF is not susceptible to attack by UV light, so the resin does not break down on exposure to sunlight which gives a very high resistance to fading and chalking and a very good long-term maintenance of gloss and color.

| Type of Alloy | 3003 H18 / 3105 H18 |

| Thickness | Up to 0.50 mm |

the WELLBOND is a newly developed composite panels that can be used in place of conventional PE, and FR core panels. This is also applicable in place of Honey comb and solid cladding sheets.

1. Thickness . 3 mm, 4 mm, 6 mm

2. Width : 1240 mm Note: 1520 mm and 1570 mm are available upon request.

3. Length : 3200 mm Provision: or under customer’s requirement between 2000- 6000 mm. Note: WELLBOND standard in stock is 3200 x 1240 mm (L x W).

| Size | Permissible Tolerance (E0S — 7630) |

| Length, mm | ±3 |

| Width, mm | ±2 |

| Thickness, mm | ±0.2 |

| Deviation of diagonal, mm | ≤5 |

| Out of straight at sides, mm/m | ≤1 |

| Warp, mm/m | ≤5 |

Email

[email protected]

Head Office

7 Sunrise Towers, Sheikh Kamel Khader, Eighth District, Nasr City, Cairo

(+20) 23524412

Copyright © Wellbond, 2024 All Rights Reserved